With a big new CMS 5-Axis CNC 25 feet long, 16 feet wide and 6.5 feet high, Cartesius can mill plugs, molds, and even parts of almost any size. The CMS Poseidon is best of breed for precision and robustness and is capable of milling both composites and light metals.

The product machined here was an interesting look at hand-built vs digital design. We took a cylindrical part made from a hand-built mold, covered it in tooling putty and then milled it to the proper design dimensions in our large format 5-Axis CNC. The part was originally white so everything NOT white in the result was a defect in the hand-mold process. There was very little white showing when we were done. Call us to discuss more examples of product improvement from digital modeling.

Cartesius Machining starts with generation of the numerical machine code and a model of the tool path; simulation that provides metrics, optimization, and assurance of a safe operation. The software is a companion to the 3-D CAD program and models the CNC code for the CNC machining operation. Cartesius can use your 3-D model or build one for you by laser scanning a part or building from drawings or the back of an envelope.

Cartesius uses 3-D CAD to design the buck to hold the plug or mold and then builds quality tools able to withstand transportation and shop stress. Steel frames and top qulity milling material will assure that they last as long as needed.

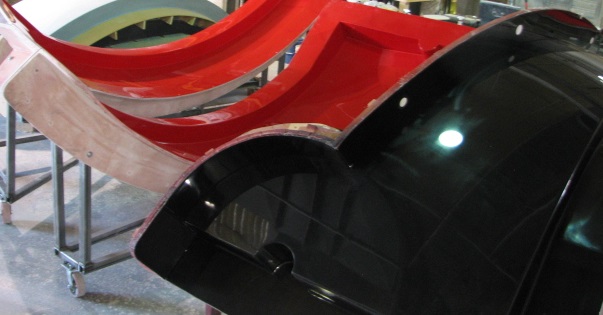

Typically high density foam on a steel frame buck that is rough milled before Tooling Putty is applied for a finish mill. Many customers apply finish coat them selves but Cartesius can finish the plug and create the mold as well.

When tooling is complete, the Laser Scanner can reveal the exactness of the final product . Metrology is the science of precise measurement of things and Cartesius uses the Creaform Laser Scanning system to scan the tooling or production part to determine how matches the reference model. Take a look at this video to see how a plug scan is compared to the 3-D CAD model.

Whether you choose to have Cartesius fabricate your end tooling or do it yourself, you will be assured the precision and accuracy you need and can achieve a Class A finish right out of the mold.

You are in the driver’s seat with respect to the detail an breadth of the program but with decades of aerospace engineering background Cartesius will offer you a well managed solution. Take a look at this video to see end to end production of a product.